In today’s rapidly evolving electronics market, the demand for efficient and reliable power supply solutions is more pressing than ever. Among the most critical components in modern power electronics is the high-frequency transformer core for inverter power supply. These components are essential for converting electrical energy efficiently and reliably, ensuring the smooth operation of devices across retail and industrial applications. Understanding the significance of high-frequency transformer cores in inverter power supplies can help retailers, engineers, and manufacturers optimize their product offerings and improve customer satisfaction.

Understanding High-Frequency Transformer Cores

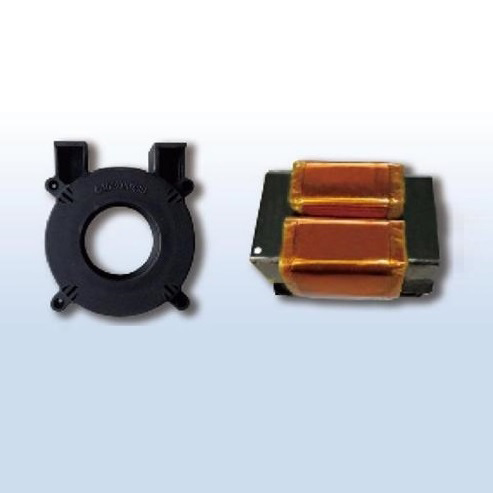

High-frequency transformer cores for inverter power supply are specialized magnetic cores designed to operate at higher frequencies than traditional transformers. Unlike standard transformers that typically function at 50 or 60 Hz, these cores can operate efficiently at tens to hundreds of kilohertz. This high-frequency operation offers several advantages, including smaller size, lighter weight, improved energy efficiency, and reduced electromagnetic interference (EMI).

The core material plays a crucial role in the performance of the transformer. Common materials include ferrite, powdered iron, and nanocrystalline alloys, each offering unique properties in terms of permeability, saturation flux density, and core loss. Selecting the right high-frequency transformer core for an inverter power supply depends on the application requirements, such as power rating, operating frequency, thermal performance, and mechanical constraints.

Importance in Inverter Power Supplies

Inverter power supplies are critical for converting direct current (DC) to alternating current (AC) in various electronic devices, from household appliances to industrial machinery. The high-frequency transformer core is central to this conversion process, enabling efficient energy transfer while minimizing losses. Using a high-frequency transformer core for inverter power supply allows the inverter to operate at higher switching frequencies, which directly translates into better voltage regulation, faster transient response, and reduced size of passive components like capacitors and inductors.

Moreover, high-frequency operation improves the overall system efficiency, which is particularly important in applications where energy consumption and thermal management are critical. For retail solutions, this means offering products that are not only reliable but also energy-efficient, meeting both regulatory standards and consumer expectations.

Advantages of High-Frequency Transformer Cores in Retail Applications

Retailers and manufacturers can leverage high-frequency transformer cores for inverter power supply to differentiate their products in a competitive market. Some of the key advantages include:

- Compact Design: High-frequency transformer cores allow for smaller transformers, which reduces the overall footprint of the power supply. This is especially valuable in retail electronics where compact devices are increasingly in demand.

- Energy Efficiency: By operating at high frequencies, these cores minimize energy losses, contributing to more energy-efficient power supplies. This aligns with global trends towards sustainability and low-power electronics.

- Improved Thermal Management: Efficient cores reduce heat generation, leading to lower cooling requirements. For retailers, this translates into products with longer lifespans and lower maintenance costs.

- Enhanced Reliability: High-frequency transformer cores are designed to handle rapid switching and high thermal loads, making inverter power supplies more robust. This reliability is crucial in retail applications where product failure can result in customer dissatisfaction and warranty claims.

Selection Criteria for High-Frequency Transformer Cores

Choosing the right high-frequency transformer core for inverter power supply requires careful consideration of several factors:

- Frequency Range: Ensure the core material supports the target operating frequency of the inverter. Ferrite cores are commonly used for high-frequency applications due to their low core losses at high frequencies.

- Power Handling Capability: The core must handle the intended power level without saturation or excessive heat generation. Oversized cores can increase costs and size unnecessarily, while undersized cores can lead to performance issues.

- Thermal Performance: Evaluate the core’s thermal limits and its ability to dissipate heat. Efficient thermal management prevents degradation and maintains consistent performance.

- Mechanical and Magnetic Properties: Consider permeability, saturation flux density, and core geometry. These characteristics affect the efficiency and voltage conversion ratio of the transformer.

- Cost and Availability: For retail solutions, sourcing cores that balance performance with cost-effectiveness ensures competitive pricing without compromising quality.

Applications in Retail Electronics

High-frequency transformer cores for inverter power supply are widely used across various retail electronics. Some common applications include:

- Consumer Electronics: Devices such as laptops, gaming consoles, and smart home appliances benefit from compact, efficient inverter power supplies utilizing high-frequency cores.

- LED Lighting Systems: LED drivers often require high-frequency operation to maintain stable current and prevent flicker. High-frequency transformer cores enable efficient energy conversion and long lifespan.

- Uninterruptible Power Supplies (UPS): In UPS systems, high-frequency transformer cores ensure reliable DC-to-AC conversion with minimal losses, providing backup power for sensitive electronic equipment.

- Home Appliances: Refrigerators, air conditioners, and microwave ovens increasingly rely on inverter technology to improve energy efficiency and performance, making high-frequency transformer cores indispensable.

Trends and Innovations

The market for high-frequency transformer cores for inverter power supply is constantly evolving. Recent innovations include:

- Advanced Core Materials: Researchers are developing new ferrite compositions and nanocrystalline alloys that reduce core loss and increase thermal tolerance.

- Miniaturization: High-frequency operation enables more compact power supply designs, allowing manufacturers to offer sleeker, lightweight consumer products.

- Integration with Power Electronics: Integration of transformer cores with other components such as MOSFETs and controllers reduces assembly complexity and improves overall efficiency.

- Sustainability Focus: As energy efficiency regulations tighten worldwide, high-frequency transformer cores contribute to greener electronics, an appealing feature for environmentally conscious consumers.

Challenges and Considerations

Despite their advantages, implementing high-frequency transformer cores in inverter power supplies comes with challenges. High-frequency switching can cause electromagnetic interference (EMI), requiring careful layout design and shielding. Moreover, thermal management remains a critical factor, as compact cores can concentrate heat in small areas.

Retailers and manufacturers must also consider supply chain stability and cost fluctuations in magnetic materials. Ensuring consistent quality and availability of high-frequency transformer cores is essential to maintain reliable product performance.

Conclusion

High-frequency transformer cores for inverter power supply play a vital role in modern electronics, enabling efficient, compact, and reliable power conversion. For retail solutions, investing in high-quality cores ensures products meet performance expectations while maintaining energy efficiency and consumer appeal. By understanding the benefits, selection criteria, and applications of these cores, manufacturers and retailers can offer superior electronics solutions that cater to today’s high-demand market.

Incorporating high-frequency transformer cores not only improves product performance but also positions brands as innovators in energy-efficient and reliable electronics, a key differentiator in the competitive retail landscape.